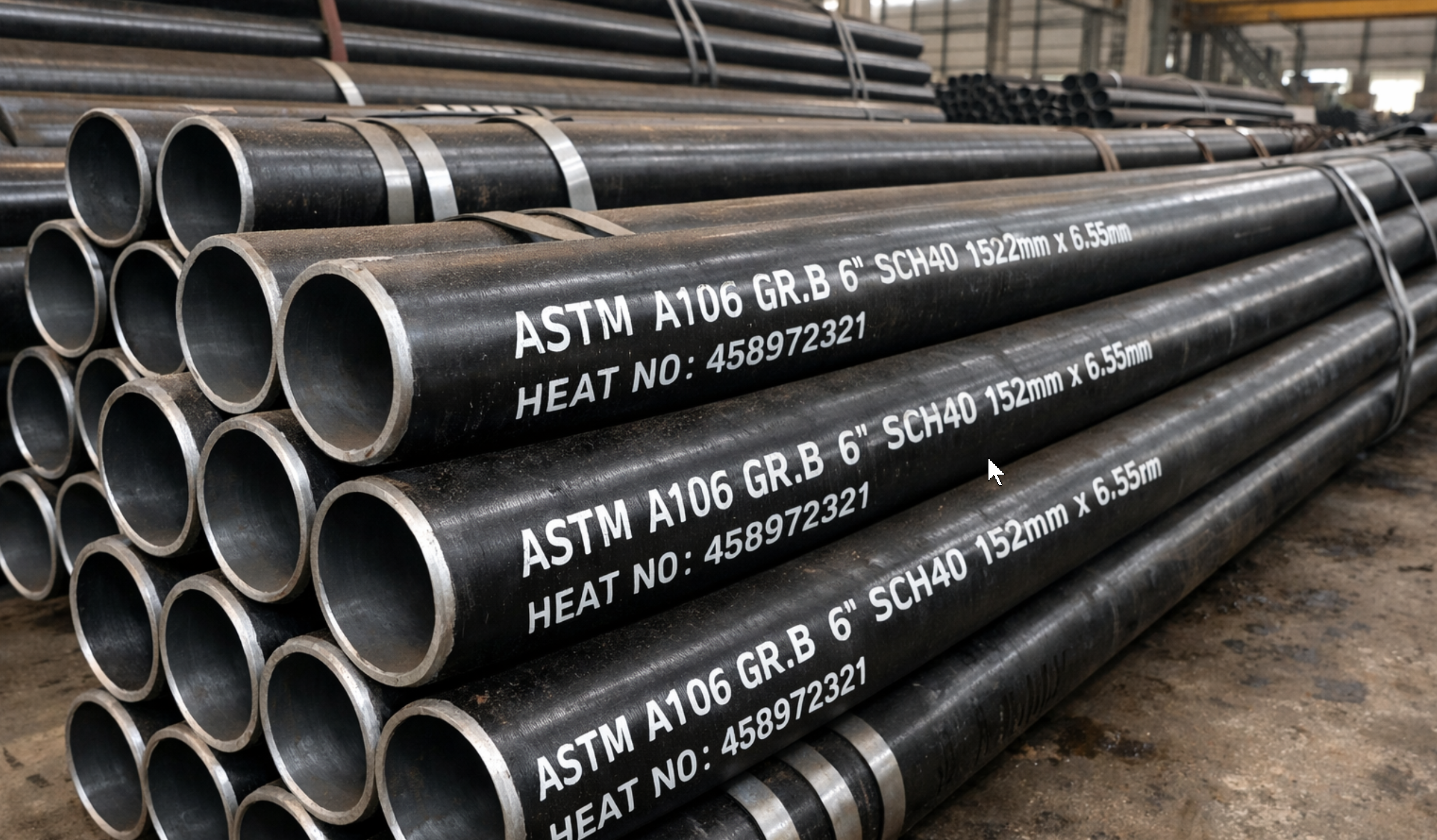

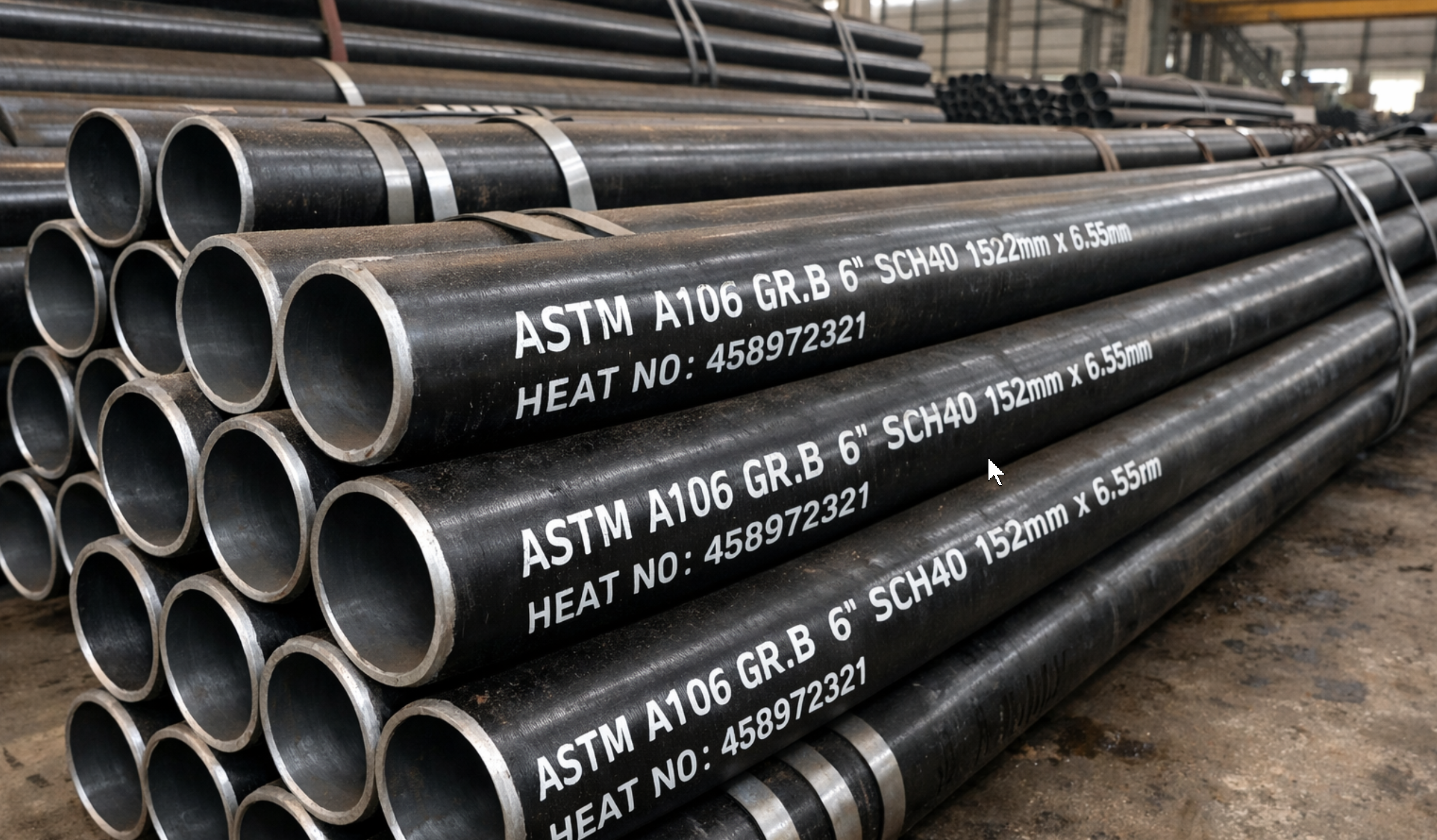

As a leading carbon steel pipe manufacturer,Rui Xiang Steel provides high-performance ASTM A106 Grade B seamless pipes. Designed specifically for high-temperature and high-pressure applications, our A106 Gr.B pipes are widely used in power plants, oil and gas refineries, and industrial boiler systems worldwide.

Technical Specifications & Standards

Our

ASTM A106 Grade B carbon steel pipeis manufactured to meet the most stringent industry requirements. Whether you need

Schedule 40 or Schedule 80 thickness, we ensure every pipe undergoes rigorous testing.

- Material:ASTM A106 Grade B (Gr.B)

- Size Range:1/2” to 36” (DN15 - DN900)

- Wall Thickness:Sch10, Sch20, Sch40, Sch80, Sch160, XXS

- Surface Treatment:Black painting, Galvanized, or Anti-corrosion oil.

Why Choose Our A106 Gr.B Seamless Pipes?

- High-Temperature Resistance:Perfect for conveying fluids and gases at elevated temperatures.

- Excellent Bendability:Ideal for flanging and similar forming operations.

- Strict Quality Control:All pipes are supplied with Mill Test Certificates (MTC) according to EN 10204 3.1.

- Competitive Factory Price:Buy directly from the source to reduce your procurement costs.

Applications of A106 Grade B Carbon Steel Pipe

Due to its durability and strength, the

A106 Grade B seamless steel tubeis the preferred choice for:

- Refinery process piping.

- Compressed air systems.

- Steam and water transport in power generation.

- Structural supports in high-heat environments.

ASTM A106 Grade B Technical Specifications

To ensure the highest quality for high-temperature service, our

ASTM A106 Gr.B seamless pipesstrictly adhere to the following chemical and mechanical standards.

1. Chemical Composition (%)

1. Chemical Composition (%)The chemical requirements for

A106 Grade B are critical for its weldability and heat resistance.

Element

| ASTM A106 Grade B (%)

|

Carbon (C) max

| 0.30%

|

Manganese (Mn)

| 0.29% – 1.06%

|

Phosphorus (P)max

| 0.04%

|

Sulfur (S) max

| 0.04%

|

Silicon (Si) min

| 0.10%

|

Chrome (Cr) max

| 0.04%

|

Copper (Cu) max

| 0.04%

|

The low carbon content (max 0.30%) in

ASTM A106 Grade B ensures excellent weldability and ductility for high-pressure systems

2. Mechanical Properties

This table highlights why A106 B is the preferred choice for high-pressure environments compared to other grades.

Property

| Value (Metric / Imperial)

|

Tensile Strength, min

| 415 MPa (60,000 psi)

|

Yield Strength, min

| 240 MPa (35,000 psi)

|

Elongation in 2 in. (50mm), min

| Reference ASTM A106 Standard

|

FAQ About ASTM A106 Grade B Carbon Steel Pipe

Q1: What is the maximum temperature limit for ASTM A106 Grade B?

A: ASTM A106 Grade B is specifically designed for high-temperature service. It can safely operate at temperatures up to 427°C(800°F). However, if the service temperature exceeds this range for a long period, the pipe's mechanical properties may decrease, and you might need to consider alloy steel options like ASTM A335.

Q2: What is the difference between ASTM A106 Grade B and ASTM A53 Grade B?

A: This is a common question for procurement. While both are used for similar pressure ratings, the key differences are:

- Production:A106 is only seamless, whereas A53 can be either seamless or welded (ERW).

- Application:A106 is optimized for high-temperature environments, while A53 is generally used for air, water, and steam transport at lower temperatures.

- Chemical Composition:A106 contains silicon (min 0.10%) for better heat resistance, which is not mandatory for A53.

Q3: Is ASTM A106 Grade B the same as SA106 Grade B?

A:Yes, they are essentially the same.

ASTM A106 is the standard set by the American Society for Testing and Materials, while

ASME SA106 is the standard used by the American Society of Mechanical Engineers for boiler and pressure vessel codes. In most commercial cases, these two standards are interchangeable.

Q4: Can A106 Gr.B pipes be bent or flanged?

A:Yes. One of the advantages of the A106 Grade Bseamless steeltubeis its excellent ductility. It is suitable for bending, flanging, and similar forming operations. For sizes under 2 inches, it is commonly used for close coiling.

Q5: Does Rui Xiang Steel provide Mill Test Certificates (MTC) for A106 pipes?

A:Absolutely. All our carbon steel pipes are supplied with full traceability. We provide Mill Test Certificates according to EN 10204 3.1, which include chemical analysis, mechanical testing, and hydrostatic test results to ensure compliance withASTM A106standards.

"Need a Quick Quote or ASTM A106 B Stock List? [Contact Our Engineers Now]"

Not sure if you need A106 or A53? Check our [

detailed comparison guide]

Click:592Edit: Ruixiang Steel

Click:592Edit: Ruixiang Steel Time:2025-12-29 22:48:54

Time:2025-12-29 22:48:54