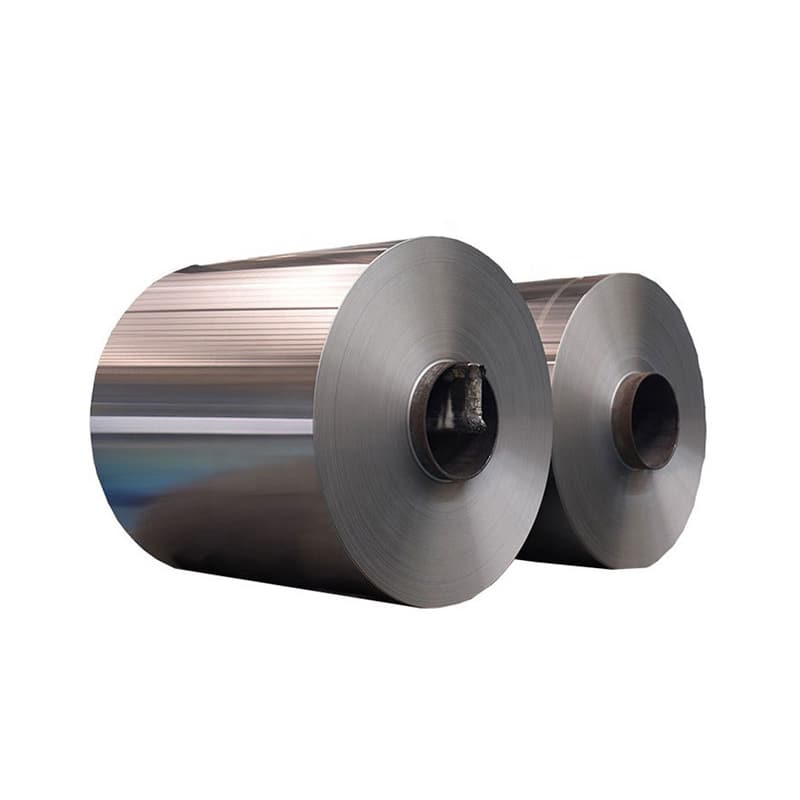

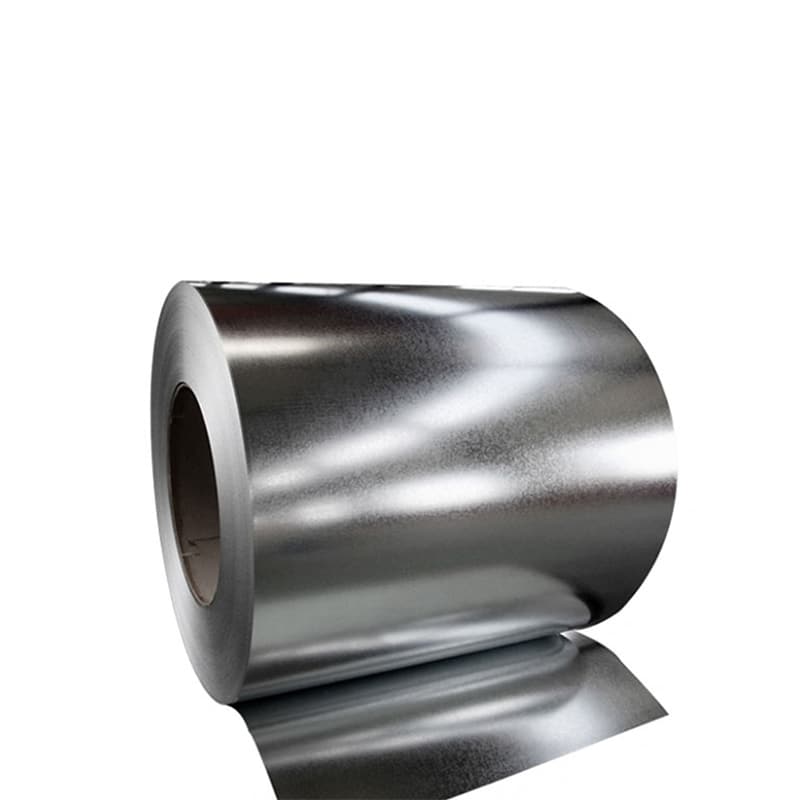

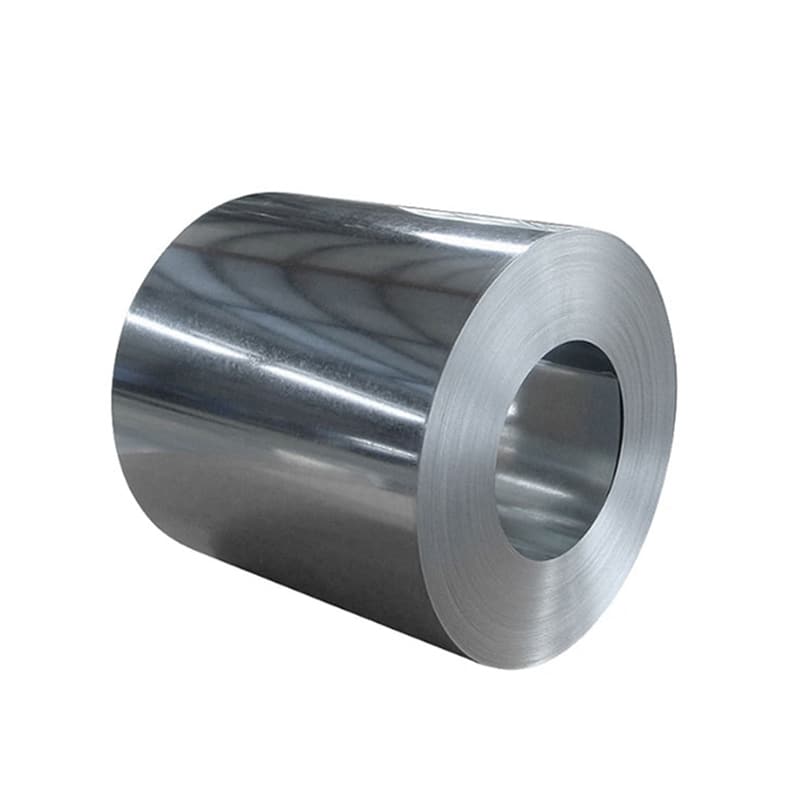

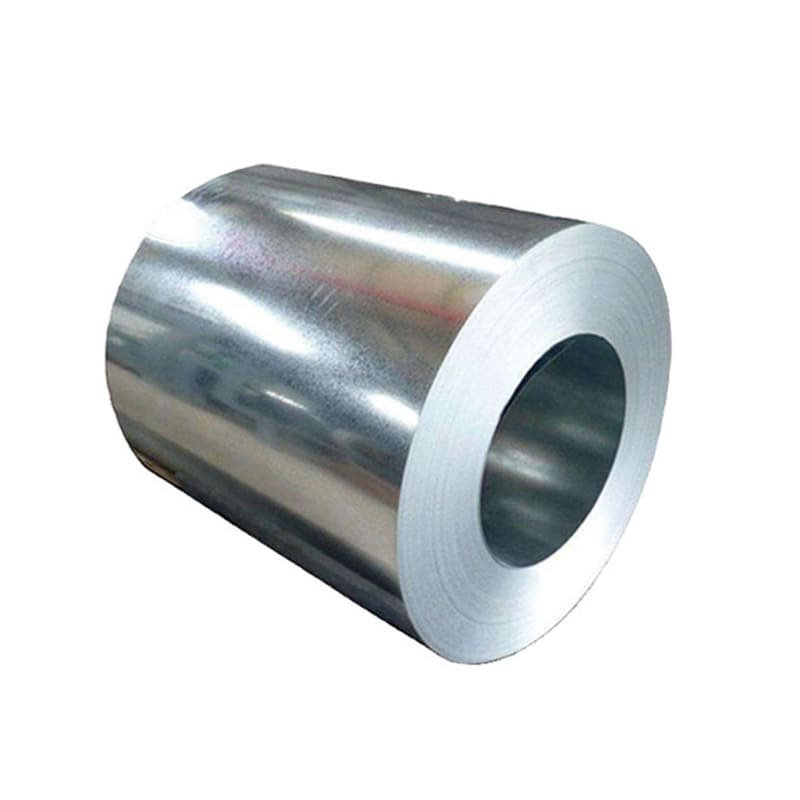

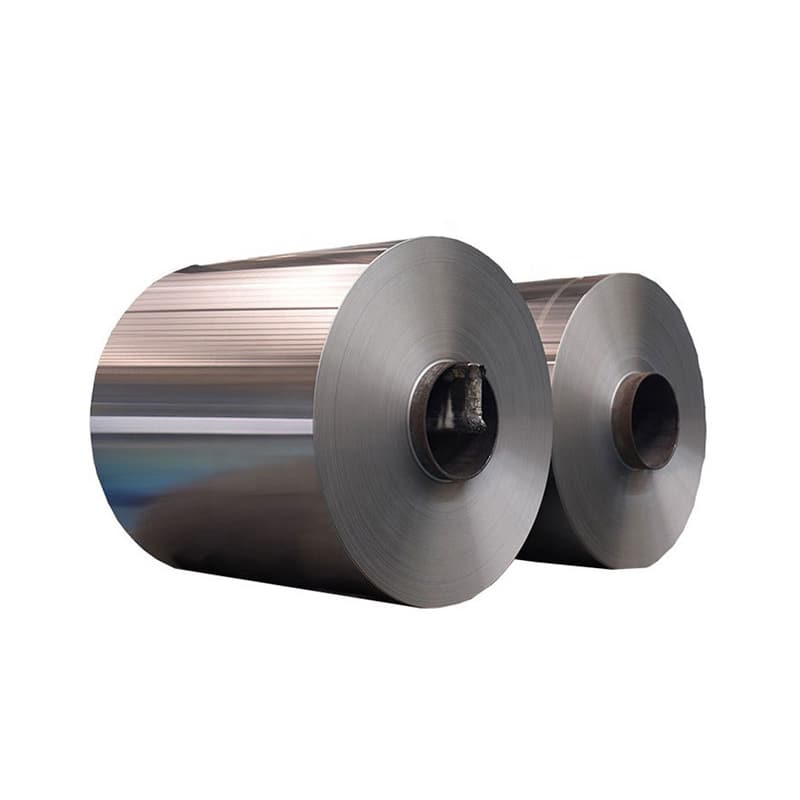

High-Performance Hot Dipped Galvanized Steel Coil (GI Coil)

Ruixiang Steel’s GI Steel Coils are engineered via a continuous hot-dipping process. This ensures a multi-layer protective coating of zinc-iron alloy for unmatched corrosion resistance. We provide custom solutions from Z40 to Z275 g/m² coating weights to meet global standards (ASTM A653, JIS G3302, EN10147).

Technical Specifications

| Base Metal | Full Hard / Cold Rolled Base Steel |

| Thickness | 0.12mm – 2.0mm (Precision Tolerance ±0.02mm) |

| Width | 600mm – 1500mm (Slitting service available) |

| Zinc Coating | 40g/m² – 275g/m² (Common: Z180, Z275) |

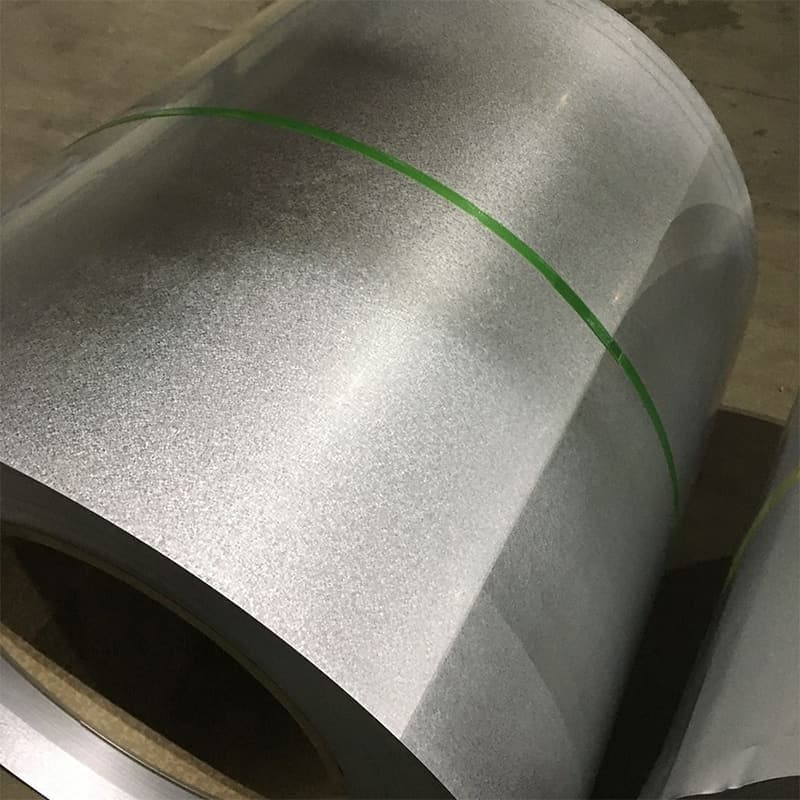

| Surface Finish | Regular Spangle, Minimum, or Zero Spangle |

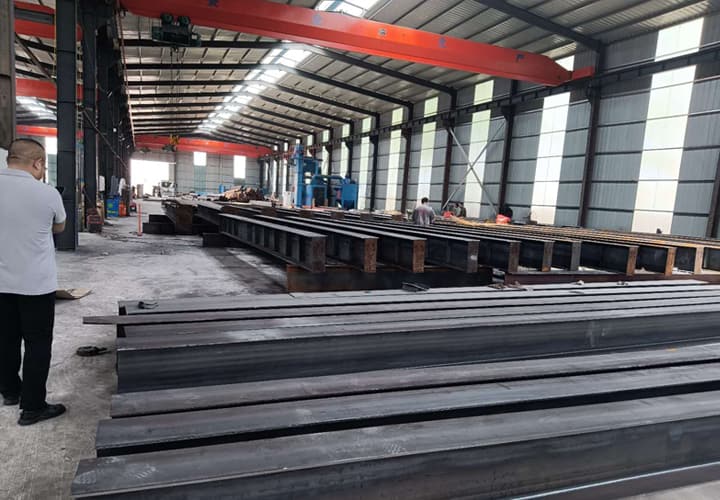

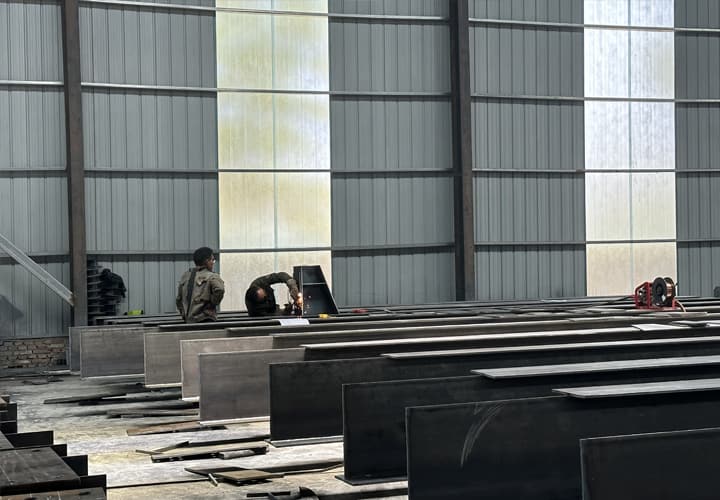

Factory-direct Prime GI Coils with Seaworthy Export Packing

Steel Grade & Application Guide

| Category | Common Grades | Typical Use Case |

|---|---|---|

| Commercial Use | DX51D+Z, SGCC, CS Type A/B | Roofing sheets, general bending, ventilation ducts. |

| Deep Drawing | DX53D+Z, DX54D+Z, SGCD | Automotive parts, complex shaped appliance panels. |

| High Strength | S350GD, S550GD, G550 | Structural purlins, high-load steel decking, framing. |

GI Coil Technical FAQ

Q: What is the benefit of Z275 zinc coating?

A: Z275 indicates 275g/m² total zinc weight (both sides). In normal outdoor environments, this provides 20+ years of rust protection without painting. It is the gold standard for high-end construction and roofing projects.

Q: How should GI coils be stored to prevent white rust?

A: Coils should be stored in a dry, ventilated environment. We offer Chromated (passivated) and Oiled surface treatments to provide extra protection during sea transit and warehouse storage.

Langue

Langue English

English русский

русский Français

Français Türkçe

Türkçe Español

Español اللغة العربية

اللغة العربية

Current Location:

Current Location:

Add Successfully

Add Successfully

Tel:+86-132 8756 7777

Tel:+86-132 8756 7777

Phone:+86-132 8756 7777

Phone:+86-132 8756 7777 Adds:701B, Shuntai Plaza 8th building,Jinan Area of the Pilot Free Trade Zone, China.

Adds:701B, Shuntai Plaza 8th building,Jinan Area of the Pilot Free Trade Zone, China.

Home

Home WhatsApp

WhatsApp Email

Email