Premium Hot Rolled Steel Coil (HRC) Supplier

Ruixiang Steel offers industrial-grade Hot Rolled Steel Coils (HRC), providing an economical and high-strength solution for heavy structural applications. Available in multiple grades including Q235, SS400, and ASTM A36.

Key Advantages & Applications

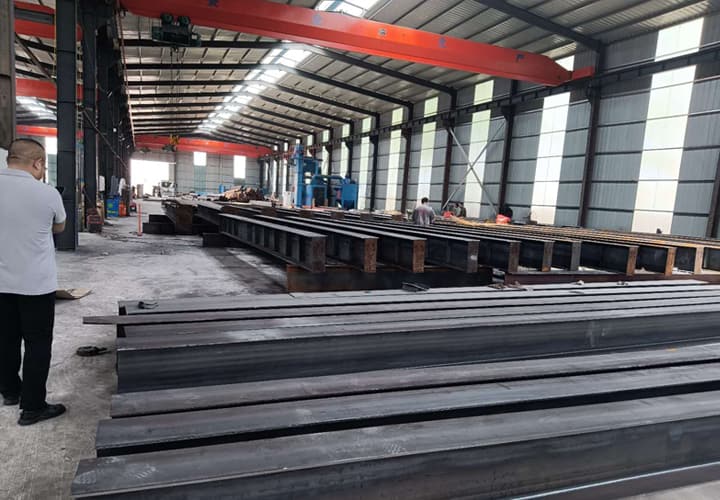

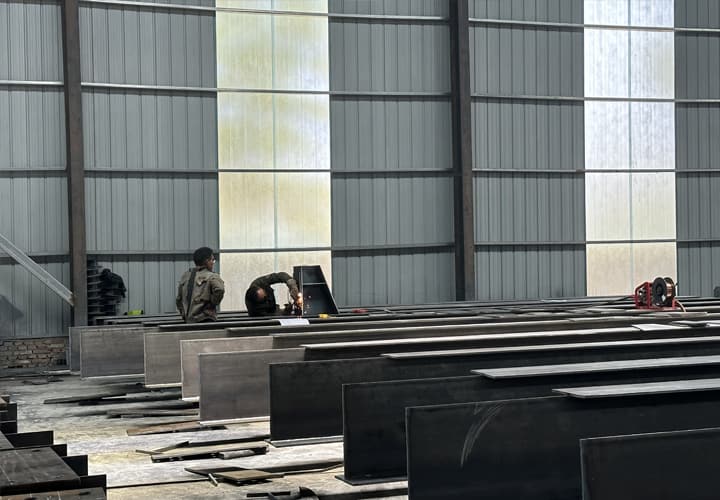

Structural Versatility

Excellent weldability and ductility make HRC ideal for manufacturing I-beams, steel structures, pipes, and heavy machinery frames.

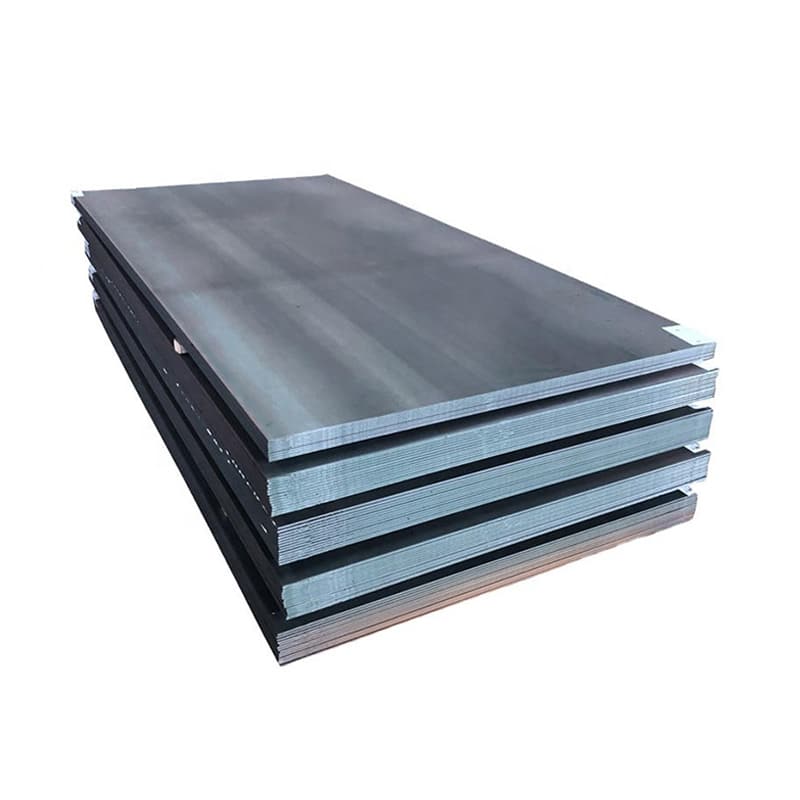

Scale Protection

Standard HRC features a natural blue-grey oxide coating that provides a basic layer of corrosion resistance during transit and storage.

Technical Specifications

| Category | Standard Range |

|---|---|

| Execution Standards | ASTM A36/A1011, JIS G3101/G3131, EN 10025, GB/T 700 |

| Material Grades | Q235B, Q355B, SS400, S235JR, S355JR, A36, SAE 1006/1008 |

| Thickness Range | 1.5mm – 25.4mm (Standard HRC) | Up to 100mm (Plate) |

| Width Range | 900mm – 2200mm |

| Surface Condition | Black (As Rolled), Pickled & Oiled (P&O), Checkered |

| Coil ID / Weight | ID: 762mm / 610mm | Weight: 15 – 28 Tons per coil |

Hot Rolled Coil FAQ

Q: When should I choose Pickled & Oiled (P&O) HRC?

A: P&O is ideal if your application requires a cleaner surface for immediate painting, welding, or laser cutting without the need for additional abrasive blasting to remove mill scale.

Q: What are the differences between HRC and CRC?

A: HRC is processed at high temperatures, making it more cost-effective but with looser tolerances. Cold Rolled (CRC) is processed at room temperature for superior surface finish and precise dimensions.

Langue

Langue English

English русский

русский Français

Français Türkçe

Türkçe Español

Español اللغة العربية

اللغة العربية

Current Location:

Current Location:

Add Successfully

Add Successfully

Tel:+86-132 8756 7777

Tel:+86-132 8756 7777

Phone:+86-132 8756 7777

Phone:+86-132 8756 7777 Adds:701B, Shuntai Plaza 8th building,Jinan Area of the Pilot Free Trade Zone, China.

Adds:701B, Shuntai Plaza 8th building,Jinan Area of the Pilot Free Trade Zone, China.

Home

Home WhatsApp

WhatsApp Email

Email